A transformer is a static electrical system whose main task is to transfer electrical energy from one circuit to another while maintaining the same frequency. The primary part of the transformer is the one that typically receives electricity, while the secondary part is the one that typically distributes the electricity. The primary is usually the side having the higher voltage or primary voltage in step down transformer. On the other hand, the secondary distributes the secondary or low voltage in the step-down transformer.

How does a transformer work?

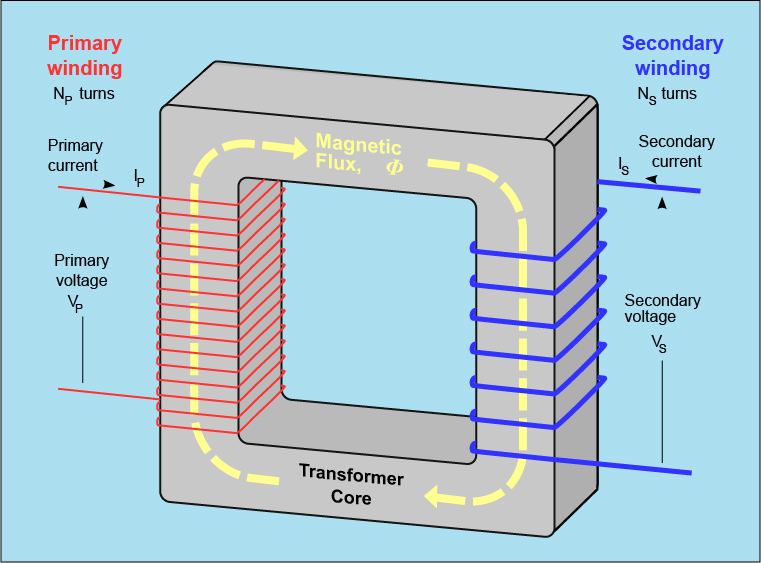

Transformer works based on mutual induction. The question may arise what mutual induction is. When an electromotive force is produced due to current shifting from one circuit to another, and the two circuits are magnetically connected is referred to as mutual induction.

When the primary coil receives an electrical supply, a magnetic field is generated, collecting the secondary coil. Consequently, electricity flows in the secondary coil due to reciprocal induction between the primary and secondary coils.

Since there are no moving parts in the transformer, it is an entirely stationary unit. It has a fundamental structure, with two or more insulated copper wires wrapped around a laminated steel/iron core.

In other words, we know that transformers have two windings, primary and secondary windings. When voltage is supplied to the primary winding, a magnetic field is created, and the magnetic flux passes through the iron core to the secondary winding, and a magnetic field is created there.

It results in voltage to the secondary coil. The amount of current flowing on the secondary side compared to the primary side will depend on the number of patches in the primary and secondary coils, called the transformation ratio.

Why it is used for transformers?

Transformers are usually used for voltage up and down voltage. For example, suppose the voltage of the sub-station is 11 kV, but 400/220 volts are required at the consumer level. Then we use a transformer to step down this 11kV voltage to 400/220 volts.

Parts of a transformer:

Primary coil

The primary coil is the side on which power is supplied to the transformer.

Secondary coil

The side from which the output is collected is called the secondary side.

Core

The frame in which the winding is wrapped in steel is called the core. The magnetic flux generated on the primary side due to steel cores can very quickly be associated with the secondary.

Winding

The winding of a transformer may have two or more coils. These coils are usually made of super enamel copper wire.

Insulation

Insulating paper is used on the core to insulate the core from the coil. The coils themselves are insulated by a super enamel coating in the patch.

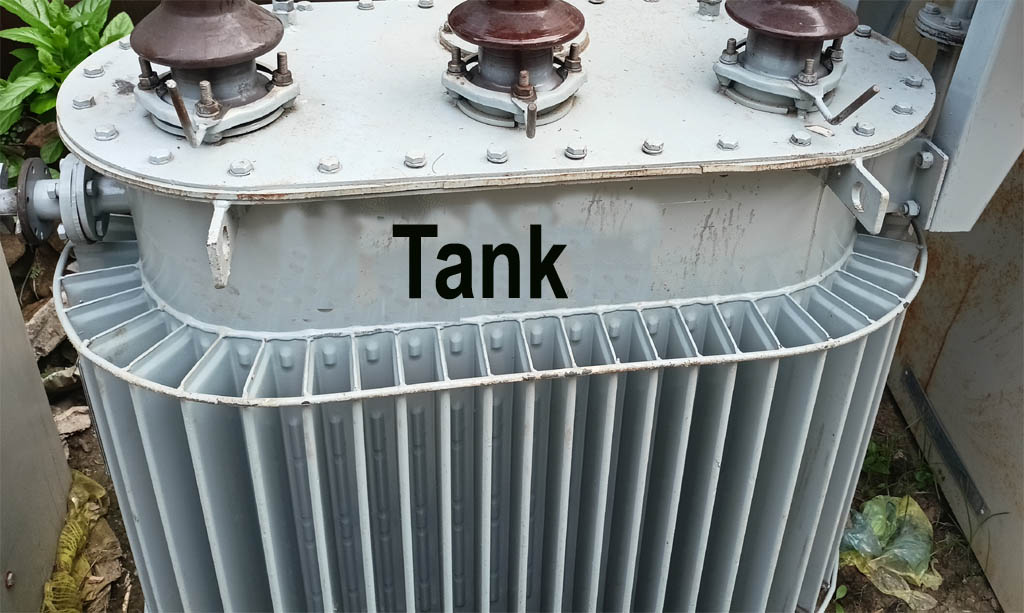

Tank

The inside of the transformer tank contains a type of oil in which the windings and cores are immersed. The tank is fitted with a climate-resistant gasket. The core is attached to the bottom of the tank.

Transformer oil

The oil used inside the tank is the transformer oil. It is commonly used for insulation and to keep the windings cool.

Conservator

The oil volume of the transformer decreases as the oil heats up and cools down. One drum type is used on the tank to solve the increase-decrease problem. This drum is called Conservator.

Breather

A type of glass vessel called a breather is used to keep the air flowing inside the transformer free of flammable vapor and dry as the oil volume of the transformer increases or decreases.

Bushing

The winding terminals used in transformers are brought out of the tank by a bushing. The primary coil is connected to the AC source and the secondary coil to the load through this bushing.

Earth Point

The body of the transformer has two earth points to protect it from various types of accidents. These earth points are connected to two soils.